Optimize your supply chain footprint for resilience, speed, and profitability.

Design smarter, faster, and more resilient supply chain networks.

Model, simulate, and optimize your global network across plants, warehouses, and transport routes — all on one AI-driven platform.

Problem Statement

Supply chains today face rising logistics costs, inefficient facility locations, and slow, manual decision cycles. Static network models fail to adapt to changing demand, taxes, and trade dynamics, costing millions in inefficiencies. Impact: Most global manufacturers reassess their network once every 5 years, but the market now changes every 6 months.

Solution Overview

Key Features & Capabilities

- Powerful Optimization Engine

- Advanced MILP and AI-driven solvers for cost-efficient, resilient networks.

- Scenario Planning & What-If Simulation

- Compare multiple strategies from DC relocations to market expansions instantly.

- No-Code / Low-Code Deployment

- Rapid setup with ready-to-deploy templates; minimal IT dependency.

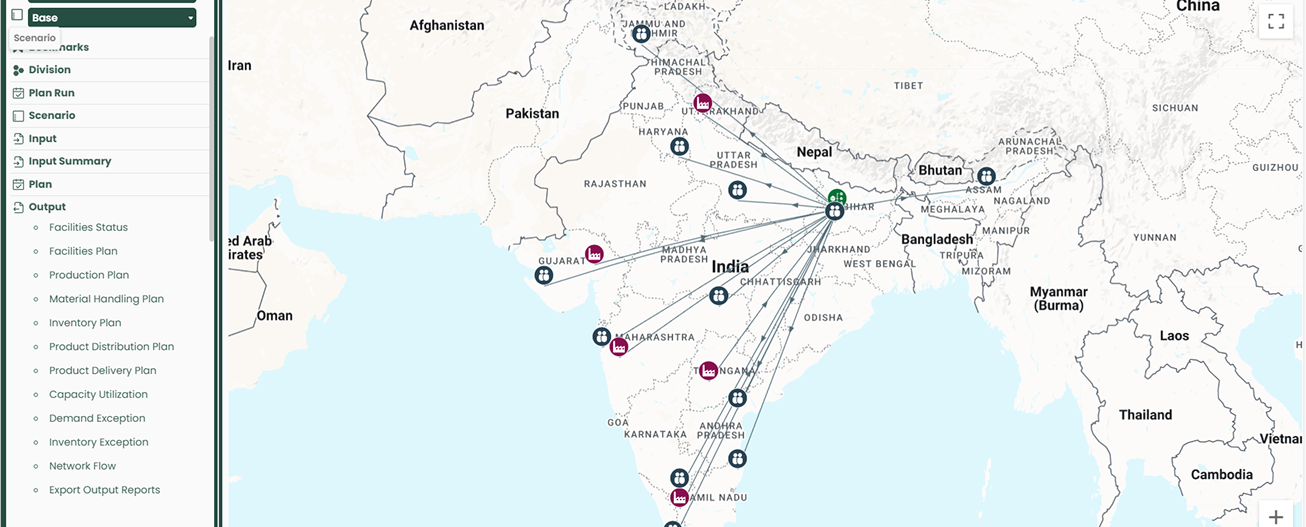

- Geospatial Visualization

- Interactive map view to visualize facilities, flows, and lanes.

- Flexible Integration

- Connects seamlessly with ERP, TMS, WMS, Excel, and APIs for real-time updates.

- Custom Constraint Modelling

- Account for taxes, ESG goals, and risk factors directly in the optimization model.

Business Impact

Cost Optimization

5–15% reduction across facilities, transport, and logistics

Setup Efficiency

Reduce setup and changeover losses by up to 20%

Delivery Performance

Improve OTIF with faster, more reliable fulfillment

Strategic Resilience

Proactively model disruptions and demand spikes

Time-to-Value

Deliver actionable results within days using prebuilt templates

Applications

- Manufacturing: Optimize factory-to-distributor layouts.

- Retail & FMCG: Plan warehouses near demand hubs.

- Logistics Providers: Create dynamic, scalable routing networks.

- Sustainability Teams: Model greener, low-emission networks.

Compatibility

- ERP & Planning Systems: SAP, Oracle, Dynamics

- Transportation & Execution Platforms: TMS/WMS integration ready

- APIs & File-Based Data Exchange

- Cloud or On-Prem Deployment — hybrid-ready flexibility

Distribution Network Redesign for a Global Tyre Distributor

A leading tyre distributor faced mounting costs and service delays due to outdated distribution centers far from demand hubs. Using SCY Network Design, they simulated multiple scenarios, including DC relocation and consolidation. The optimized model recommended fewer warehouses closer to central demand clusters, cutting logistics costs by 15% while maintaining service levels. Leadership gained a clear, data-backed roadmap for phased rollout and long-term resilience.]