Digitize, visualize, and synchronize material flow across your supply chain.

Eliminate material shortages and overstock with smart, digital replenishment.

SCY E-Kanban replaces manual card systems with real-time, sensor-driven replenishment signals — enabling seamless flow between suppliers, production lines, and warehouses. Accelerate response times, cut material waste, and achieve true just-in-time efficiency.

Problem Statement

Manual Kanban systems often break down due to paper-based tracking, human error, or delays in replenishment. The result? Stockouts on the shop floor, excess inventory in stores, and reduced production throughput.

Impact: In discrete manufacturing, 70% of downtime is caused by missing parts or poor material visibility.

Solution Overview

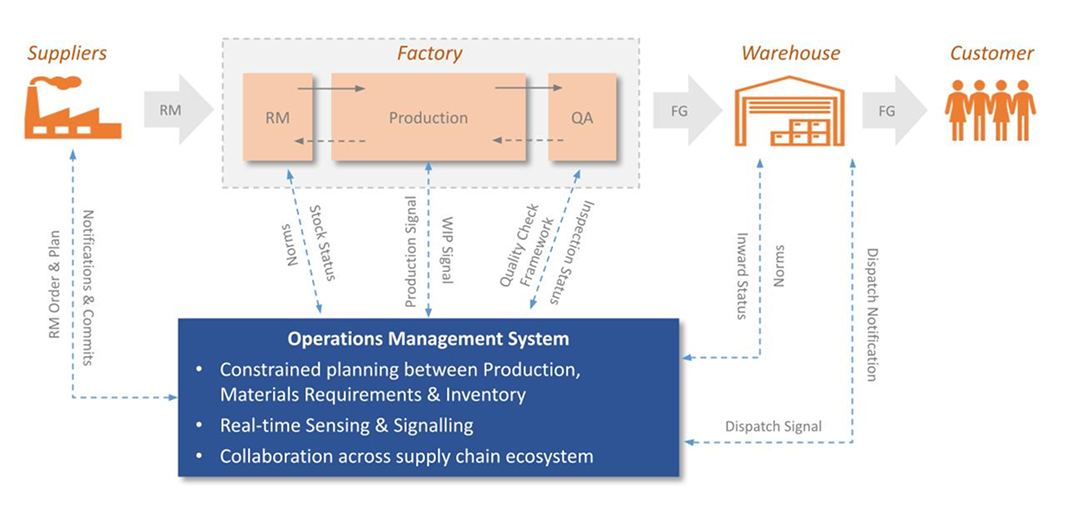

SCY E-Kanban digitizes the entire Kanban process — from signal generation to supplier communication — through IoT, barcode/RFID integration, and automated triggers.

It ensures every replenishment request is visible, traceable, and actionable in real time.

By synchronizing material movement with production schedules, SCY E-Kanban eliminates the chaos of manual tracking, reduces WIP, and increases overall equipment effectiveness (OEE).

Unlike static systems, it adapts dynamically to consumption rates, demand fluctuations, and priority changes — ensuring uninterrupted production flow.

Key Features & Capabilities

- Real-Time Digital Kanban

- Replace paper cards with live, automated replenishment triggers.

- IoT and Barcode/RFID Integration

- Connect bins, racks, and stations for hands-free signal generation.

- Dynamic Buffer Management

- Auto-adjust Kanban quantities based on actual demand and lead times.

- Supplier Collaboration Portal

- Share real-time signals with suppliers for synchronized replenishment.

- Analytics Dashboard

- Visualize material flow, lead times, and bottlenecks with actionable insights.

- ERP Integration

- Seamlessly connects with SAP, Oracle, and other ERP systems for end-to-end visibility.

Business Impact

Real-Time Visibility

End-to-end visibility across production and supply lines

Supplier Performance

Enhanced supplier responsiveness and accountability

Operational Efficiency

Shorter replenishment cycles and improved OEE

Inventory Reduction

Reduced WIP and inventory by up to 25%

Production Continuity

Eliminated material shortages and line stoppages

Automotive Tier-1 Supplier – From Chaos to Flow

A Tier-1 auto parts supplier relied on manual Kanban cards and Excel tracking for replenishment. Frequent part shortages caused production delays and emergency shipments.

After implementing SCY E-Kanban, the system connected 14 production lines and 30 suppliers through digital signals. RFID-based bins triggered replenishment in real-time, reducing WIP by 28% and improving production uptime by 15%.

With visibility dashboards, planners could anticipate shortages and proactively manage supplier lead times